Modern engines, with their exceptional horsepower-per-liter outputs walk a thin tuning line. When E85 comes into the equation, Innovate’s ECB-1 combo boost, ethanol content, air/fuel ratio, and fuel temperatue gauge helps make monitoring critical tuning paramaters a breeze.

High-performance engines ride the cutting edge of calibration in order to deliver output that, at one point, might have seemed unimaginable. This is especially the case with modern engines that automakers have engineered to deliver high performance with greater efficiency. To do so, many have resorted to reducing displacement for fuel efficiency while improving fuel delivery, volumetric efficiency and adding forced induction to extract more output.

This effort results in 2.0-liter turbocharged engines generating over 300 horsepower or 3.8-liter engines producing more than 550 horsepower using premium unleaded pump fuel with daily driven consistency. Tuning and modifying these engineering marvels raises the output to incredible levels, with the more heavily modified engines doubling, tripling and even quadrupling the factory specifications.

Of course, there is a fine line between a safe and reliably calibrated engine and a damaged one. This is especially true for performance engines operating under high cylinder pressures at high engine speeds. To stay on the right side of that line requires monitoring of your engine’s vital signs. Unfortunately, the automakers equip the typical vehicle with only three-to-four basic instruments, including a speedometer, fuel-level gauge, water temperature gauge and, if you’re in a reasonably equipped car, a tachometer. Otherwise, the only other indicators are a field of idiot lights that tell you very little.

The ECB-1 includes everything necessary for installation. Even newer performance platforms like the Mitsubishi Lancer Evolution X offer just the most basic of gauges to the driver, despite having incredible performance potential. With a factory rating of 291 horsepower at the crank (approximately 250 horsepower at the wheels) the EVO X is a decent performance platform from the factory.

Once you’ve upgraded it with an intake, intercooler, downpipe, exhaust, camshafts, a turbo upgrade and a flex fuel conversion kit, more boost pressure and the appropriate calibration step up the output to 475 horsepower at the wheels. At nearly double the factory horsepower output, knowing what’s going on under the hood becomes even more critical than ever.

Four-in-One Solution

Innovate Motorsports invests in the idea that knowledge is power. Knowing your engine’s vital signs can make the difference between detecting a problem and preventing damage versus discovering the issue after damage to the engine is done.

While it is possible to install individual gauges for each parameter being monitored, Innovate Motorsport’s engineers consolidated and streamlined four gauges into one with the release of the ECB-1 Ethanol content/Boost/Air/Fuel Ratio/Fuel Temperature gauge.

This compact 52mm diameter gauge features an Organic LED (OLED) display capable of relaying all four parameters simultaneously. The ECB gauge system includes everything you’d need to monitor these four critical variables.

A 4-BAR MAP sensor reports vacuum and boost, a Bosch LSU 4.9 wideband sensor samples the exhaust for air/fuel ratio and an ethanol content analyzer measures the temperature and percentage of ethanol in the tank. The kit includes two bezels and two face plates, providing up to four different color combinations to best complement the vehicle’s instrument cluster and interior. So why would these particular details be important to monitor?

Peril Under Pressure

Naturally-aspirated engines need only be concerned with air/fuel ratios and ignition timing to function optimally. Forced induction engines add the variable of a power adder(s) to the mix. Monitoring boost not only tells you that you’re hitting your boost target, it will also inform you when there are potential problems.

If boost pressures exceed the peak pressure the engine is calibrated for, it could be an indication that there is a boost control failure or a wastegate issue. If boost pressure falls short of the target setting, it could point to these issues or even a potential leak in the path of the charge pipe.

At 475 wheel horsepower (whp), knowing that boost pressure is constant and not exceeding the prescribed 32psi boost target becomes imperative. Anything more could lead to a blown engine, anything less would be a hamper on performance.

Get the Ratios Right

Too far rich or lean holds undesirable consequences. Too rich leads to wall wetting, where excessive quantities of fuel delivered to the cylinders rinse the engine oil from the cylinder walls. This reduction of the lubrication layer accelerates wear on the cylinders and the rings, which leads to blow by, accelerated oil consumption, loss of compression and reduced performance.

Conversely, a lean condition with too much air and not enough fuel results in increased combustion chamber temperatures that could lead to pre-ignition or detonation. This mistimed combustion of the incoming air and fuel will inevitably lead to damage or even a blown engine.

In a naturally-aspirated engine consuming unleaded fuel, the balance of air and fuel necessary for complete combustion of the fuel, known as stoichiometric (or stoich), is a ratio of 14.7-to-1. Based on this standardized ratio, too much fuel (air/fuel ratios below 14.7-to-1) is recognized as a rich condition. Too much air results in a lean condition (air/fuel ratios greater than 14.7-to-1.) When high-performance forced induction is thrown into the mix, running a richer air/fuel ratio is preferred by most engine calibrators, with targets ranging from 11.0- to 12.0-to-1. These ratios ensure plenty of fuel delivery to avoid a lean and potentially catastrophic condition. When it comes to other fuels like leaded race fuel, E85 and diesel, the target ratios will be a bit different for each.

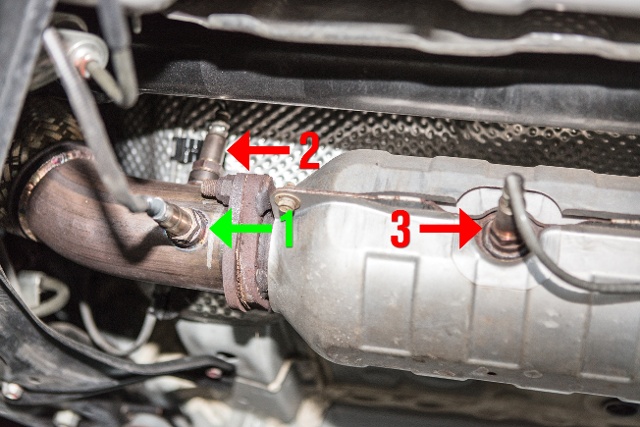

The ECB-1 includes a Bosch LSU 4.9 wideband sensor that is compatible with a variety of fuels including unleaded pump gasoline, E85, diesel and leaded race fuel. The kit includes a 1-inch bung that must be welded into the downpipe, ideally 24-inches after the turbocharger, or the exhaust ports on naturally aspirated engines, but before the catalytic converter. Unlike the factory and previous generations of oxygen sensors, the LSU 4.9 does not need to be directly in the exhaust flow. This longer O2 sensor bung shields the sensor probe to ensure an optimal service life. Depending on the type of fuel being sampled, the lifespan of the sensor will vary, as certain fuels (like leaded race fuel) will foul the sensor more quickly than others.

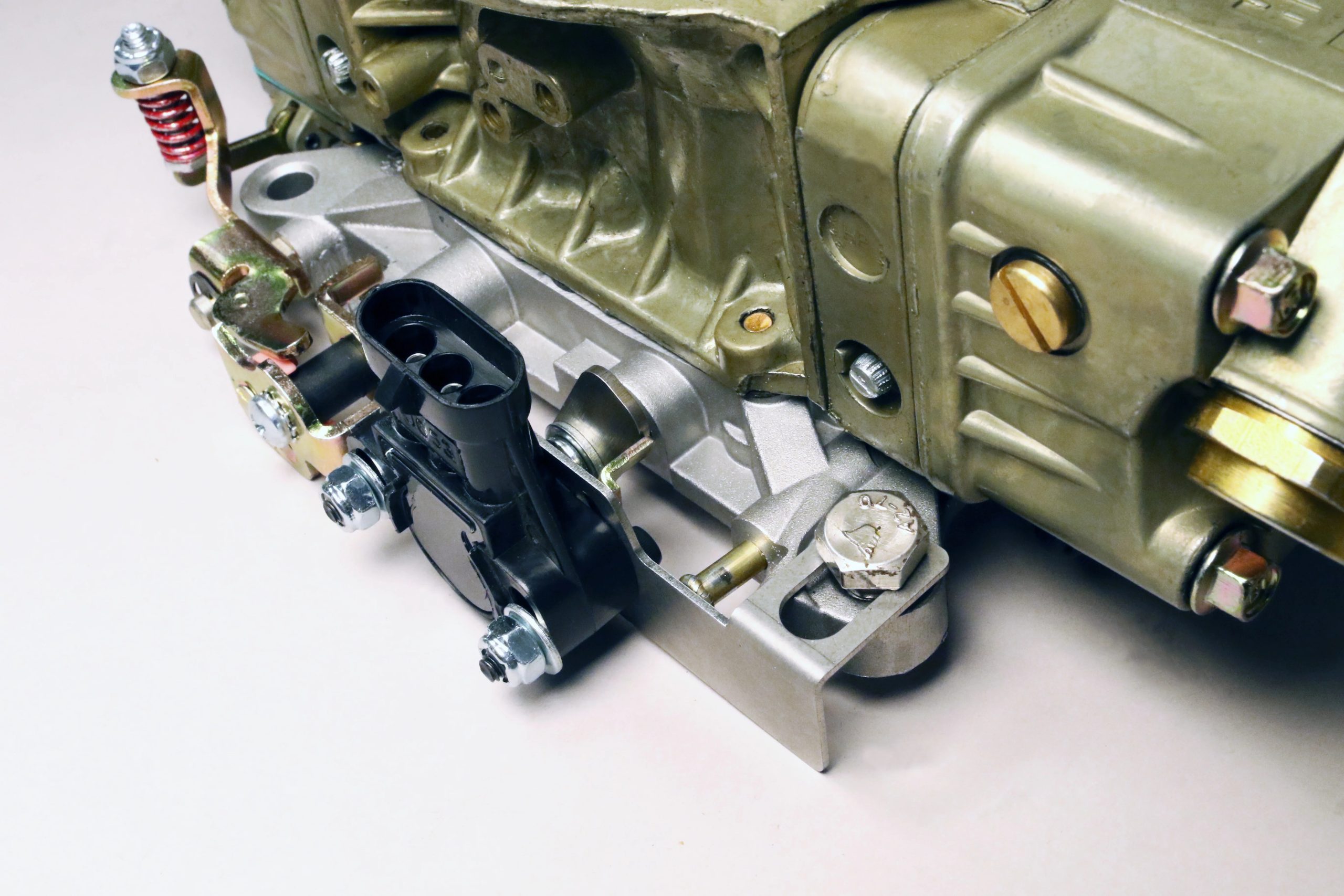

The -6AN fittings mount directly to the Ethanol Content Analyzer. The fittings, sensor and fuel line mount directly between the fuel outlet and the fuel feed line.

High Price of Performance

Reaching higher output levels depends heavily on the fuel in the tank. Premium unleaded fuel has its limitations, even if the engine has been fortified with an aftermarket rotating assembly. Racers calibrated their engines to run on such leaded race fuels as C16 or VP Import in order to reach higher output levels. Of course, paying $25-per-gallon or more for race fuel made high output engines cost prohibitive to run on the street, not to mention, not legal.

Farmed Fuel

In the mid 2000s, skyrocketing US fuel prices and government subsidies prompted a concerted effort to incorporate more renewable energy sources to reduce consumer dependence on petroleum pump fuels.

One product, E85 (Ethanol 85, or 85% ethanol, 15% gasoline), began to gain traction since the “Heartland of America” produced a healthy volume of corn, the key ingredient in the distilling of ethanol.

This soon became the answer to the prayers of high performance enthusiasts who had access to this amazing fuel.Keep in mind, E85 is not a perfect alternative, as its nuances aren’t always accounted for in vehicles not intended to run Flex Fuel (unleaded fuel, pure E85 and any mixture of the two).

For a non-Flex Fuel vehicle, the fuel delivery must be fortified to ensure at least 40% more fuel delivery to reach a given horsepower level (compared to the volume required using race fuel.) In addition, E85’s inherent hydrophilic properties necessitate a fuel delivery system designed to resist corrosion. Thus, preparation for E85 requires a higher flowing fuel pump(s) and larger fuel injectors that are compatible (corrosion resistant).

Cheap Race Gas at the Pump

For this EVO X, converting to Flex Fuel not only permitted the use of this renewable fuel source, it also increased its performance potential. The chemical cooling properties of E85 permit more aggressive ignition timing and greater boost levels. On this setup with pure 91 octane in the tank, peak boost pressures were limited to 26.6psi and delivered peak output at 351.74whp. With pure E85 in the tank, peak boost was raised to 32psi, injector duty cycle increased and ignition timing was advanced, yielding a much greater output of 475.46whp.

The EVO X center console happens to have several convenient storage compartments within easy reach of the driver’s seat. This makes accessing and activating the discreetly located PL-1 easy, especially when lined up and ready to go hot on the track.

Temper the Temperature

Another variable that the average consumer isn’t conscientious of is fuel temperature. As fuel is pumped through the fuel lines, up through the fuel rail and (in the case of return systems) then brought back to the tank by way of a fuel return line, its temperature can increase. When fuel is warm, it is less dense and burns more quickly. Conversely, when fuel is cold, it is more dense and tends to burn more slowly. These factors can affect the calibration and performance of your engine. This is particularly important at the track when track temperatures and elevated engine temperatures can affect the temperature of the fuel and the engine calibration.

Gauge Data, Acquired

Innovate Motorsports was thoughtful in its planning of the MTX series, knowing that data is useless if not collected and analyzed. With its serial interface, the ECB-1 and any of the MTX series of gauges can be linked together and recorded to a removable Secure Digital (SD) card by way of Innovate Motorsports’ Pocket Logger PL-1. Don’t be fooled by the Pocket Logger’s diminutive size. Its capable of recording up to 32 channels while sampling at 12-times-per-second. The included 2GB SD memory card can record up to 580 hours of content, which can then be downloaded and analyzed for diagnostics of issues or to ensure proper calibration. This device requires the usual 12-volt power supply and a ground, connects to the gauges via a serial cable and records at the press of a button. This is especially useful since this EVO X makes trips to the track for HPDE events on the weekends. Recording data from the ECB-1 helps to speed up the diagnostics process in the case of any problems or equipment failures.

Clean and Concise

The Innovate Motorsports ECB-1 offers an ideal complement to a high-performance platform tuned for E85 fuel. Monitoring four important variables from a single 52mm gauge form factor, and then datalogging these channels using the PL-1 Pocket Logger keeps you informed of essential vitals while capturing data for analysis and diagnostics. These tools provide essential support for any performance build.